Stainless steel is the backbone of modern horology. From rugged dive watches to luxury chronometers, it defines the balance between beauty and durability. But not every stainless steel is equal. The term “watch grade” refers to steel that meets the demanding physical and aesthetic standards required for a wristwatch case and bracelet. To qualify, it must resist corrosion, respond well to polishing, hold fine edges during machining, and remain safe against skin contact.

Among the many stainless-steel families, two alloys dominate the industry, 316L and 904L. Each has distinct characteristics that influence not only how a watch looks but how it feels, ages, and performs. Understanding these grades explains why microbrands and established manufacturers prefer 316L, while Rolex and a few others insist on 904L, even at higher production cost.

The Rise of Stainless Steel in Watchmaking

In the early 20th century, most wristwatches were made from brass, silver, or precious metals. While these offered aesthetic appeal, they were soft, easily tarnished, and unsuitable for rugged daily wear. The introduction of stainless steel transformed the industry. This iron-based alloy, first developed in the early 1900s, contained enough chromium to form a thin, invisible oxide layer on its surface. That layer prevented rust the fundamental difference between stainless steel and ordinary iron.

By the 1930s, brands like Omega and Longines began using stainless steel in sports and military watches. It quickly became the preferred choice for cases and bracelets because it combined mechanical strength, corrosion resistance, and affordability. Over time, manufacturers experimented with various grades, refining compositions to improve machinability, polish, and comfort.

What Defines “Watch Grade” Steel

Watch-grade stainless steel is not simply a raw material , it’s the result of metallurgical precision, heat treatment, and finishing expertise. Several properties determine whether a steel qualifies as watch-grade:

-

Corrosion Resistance: Watches endure sweat, rain, and humidity. The steel must remain unaffected by chlorides, acids, or saltwater exposure.

-

Hardness and Ductility: It must be hard enough to resist scratches but ductile enough to be shaped into fine contours and threads.

-

Surface Finish: Luxury watches demand mirror-like polish, while tool watches require brushed or bead-blasted textures that remain consistent.

-

Machinability: Precision cutting, drilling, and polishing depend on steel that machines cleanly without deforming or tearing.

-

Hypoallergenic Properties: Prolonged contact with skin requires materials that minimize allergic reactions, especially to nickel.

These factors determine how a case feels on the wrist, how it reflects light, and how it withstands decades of wear.

Inside the Composition: The Science of Steel

Stainless steel is essentially an alloy of iron, carbon, and chromium, with trace elements like nickel, molybdenum, and copper modifying its behavior. Chromium is the hero element , at around 16–20%, it forms a self-healing oxide film that prevents oxidation. Nickel enhances toughness and gives steel its signature silvery luster. Molybdenum boosts resistance to pitting corrosion, which is common in saltwater environments.

The heat treatment process also affects the structure of the steel. Watch-grade steels typically have austenitic microstructures, meaning they remain non-magnetic and flexible under machining. These microstructures also allow for superior polishing and surface consistency, a necessity for fine horology.

316L: The Industry’s Workhorse

316L stainless steel is by far the most common alloy in watchmaking. The “L” stands for low carbon, meaning it contains less than 0.03% carbon to prevent carbide formation during welding or heating. It typically consists of 16–18% chromium, 10–14% nickel, and 2–3% molybdenum. This combination gives it excellent corrosion resistance, even against saltwater and sweat, and makes it hypoallergenic , one of the reasons it’s often called “surgical-grade steel.”

316L’s biggest strength lies in its versatility. It machines smoothly, allowing manufacturers to create sharp edges and fine curves without damaging tools. It also takes a uniform brushed finish or a deep, even polish. For wearers, it offers the perfect balance of durability and comfort; solid but not heavy, lustrous but not flashy.

Because it’s easier to work with, it’s the preferred choice for most watchmakers, from Seiko and Citizen to microbrands like Argos that emphasize craftsmanship over cost inflation. For tool watches and everyday wear, 316L’s performance far exceeds the demands of daily life. It resists scratches, humidity, and oxidation with minimal maintenance.

904L: The Luxury Standard

904L stainless steel represents a more specialized evolution of the alloy. Originally developed for chemical and marine industries, it offers exceptional resistance to acids, chlorides, and harsh environmental conditions. Its composition is notably richer , 19–23% chromium, 23–28% nickel, 4–5% molybdenum, and 1–2% copper. This higher alloy content gives it a finer crystalline structure, which in turn produces a brighter, more reflective polish.

Rolex began using 904L in the 1980s and eventually switched its entire lineup to this alloy. The brand’s reasoning was simple: 904L retains its shine and resists corrosion in virtually any climate. A Rolex case can withstand decades of exposure to saltwater, sweat, and humidity without developing the faint tarnish that sometimes affects 316L.

However, 904L’s advantages come with challenges. Its high nickel content can irritate sensitive skin, and its hardness makes it extremely difficult to machine. Cutting tools wear out faster, and the material demands specialized polishing equipment. Only a few manufacturers, like Rolex and Ball, have the infrastructure to handle 904L at scale. This is why it remains a hallmark of luxury, not because it’s dramatically stronger, but because it’s dramatically harder to work with.

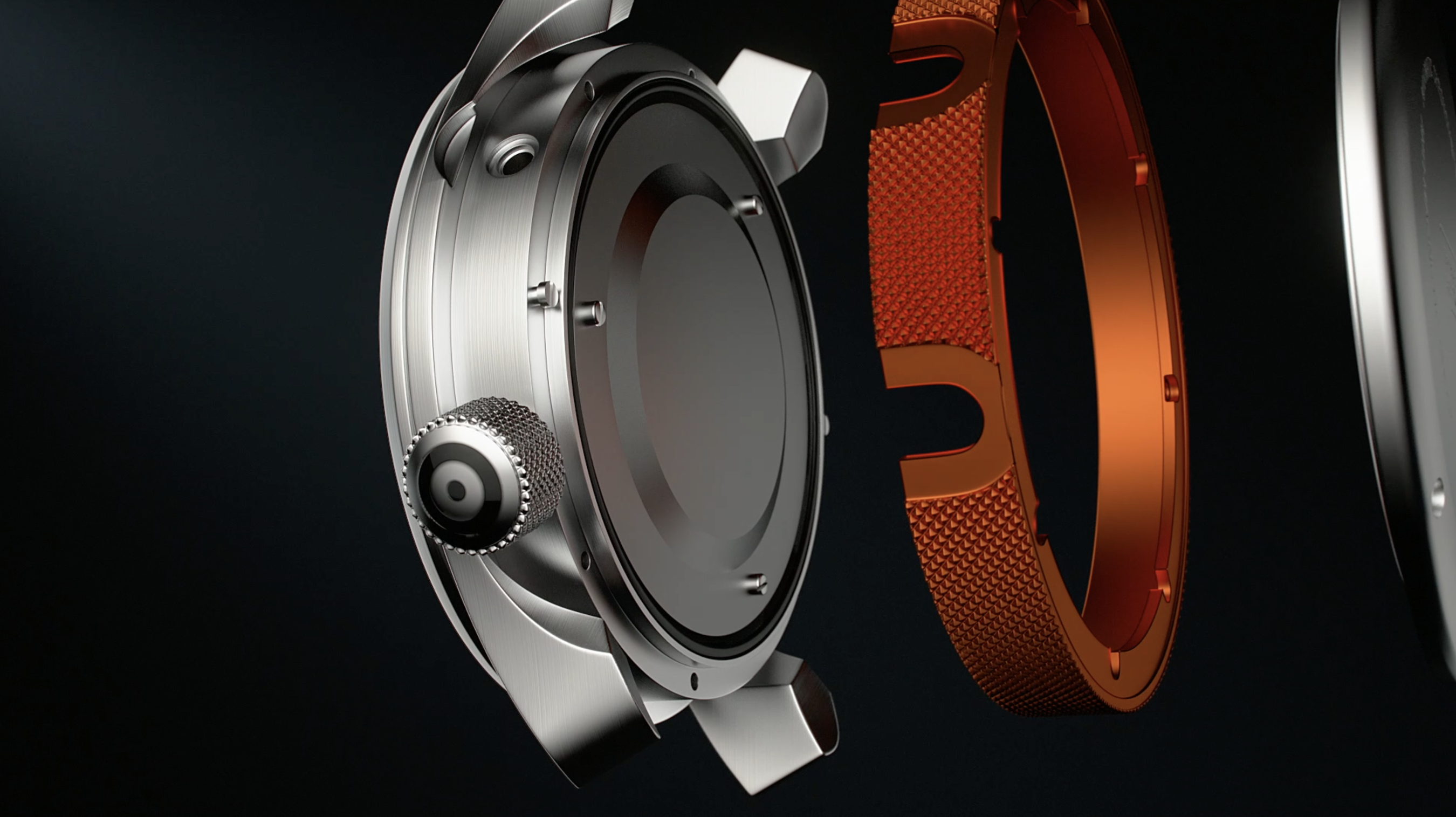

Beyond the Alloys: The Role of Finishing

Regardless of steel type, finishing defines the final character of a watch. High-end cases often combine multiple surface treatments: brushed lugs, polished bezels, and bead-blasted sides. Achieving perfect transitions between these surfaces requires steel that responds predictably to polishing compounds and abrasives, another reason 316L is so popular.

904L, thanks to its fine grain structure, can achieve an exceptionally bright, mirror-like polish that lasts longer before dulling. This characteristic is one reason Rolex watches maintain their distinct sheen even after years of wear.

Microbrands often choose to highlight the texture of 316L through brushed or matte finishes, lending their pieces a tool-watch aesthetic. When polished properly, though, a well-finished 316L case can rival the visual depth of 904L.

Why Microbrands Stick With 316L

For independent watchmakers, 316L offers a perfect equilibrium between practicality and quality. It’s affordable, accessible, and consistent. More importantly, it provides flexibility for design and repair. Cases can be re-polished during servicing without compromising the alloy’s integrity.

904L, while beautiful, offers diminishing returns for most brands. Its cost, machining complexity, and limited availability make it impractical for small-batch production. A well-executed 316L watch, especially one with excellent finishing and detailing, can rival the presence of far costlier pieces, without the maintenance challenges of 904L.

In Perspective: 316L vs 904L

The choice between 316L and 904L comes down to intent. A dive watch built for reliability and comfort performs best in 316L. A luxury piece designed to showcase flawless polish and exclusivity benefits from 904L. For collectors, the difference is more philosophical than functional: 316L represents intelligent engineering; 904L represents mastery through obsession.

In both cases, the steel’s grade matters less than the watchmaker’s craftsmanship. A well-machined 316L case with precise brushing and tight tolerances will always outshine a poorly finished 904L one.

Final Thoughts

When a manufacturer calls their material “watch grade,” they’re referring to more than metal composition; they’re referring to decades of refinement in metallurgy, heat treatment, and finishing. 316L and 904L are both extraordinary materials, each serving a different vision of watchmaking.

The microbrands that embrace 316L focus on balance, comfort, and wearability. The luxury houses that rely on 904L chase perfection in form and luster. Both paths lead to watches that endure time, not just mechanically, but materially.

Ready to elevate your wrist game?

Discover the Argos Watches Olympus and enjoy a 40 mm watch case crafted in 316L stainless steel. With a reliable automatic movement, lifetime warranty option, and exceptional value, this timepiece bridges everyday durability with elegant design. Explore it now and secure your own piece of mechanical craftsmanship.